Electronics

We create antistatic, ESD (Electrostatic Dissipative) packaging designed to protect electronics.

Defending Electronics with Static-Free Packaging

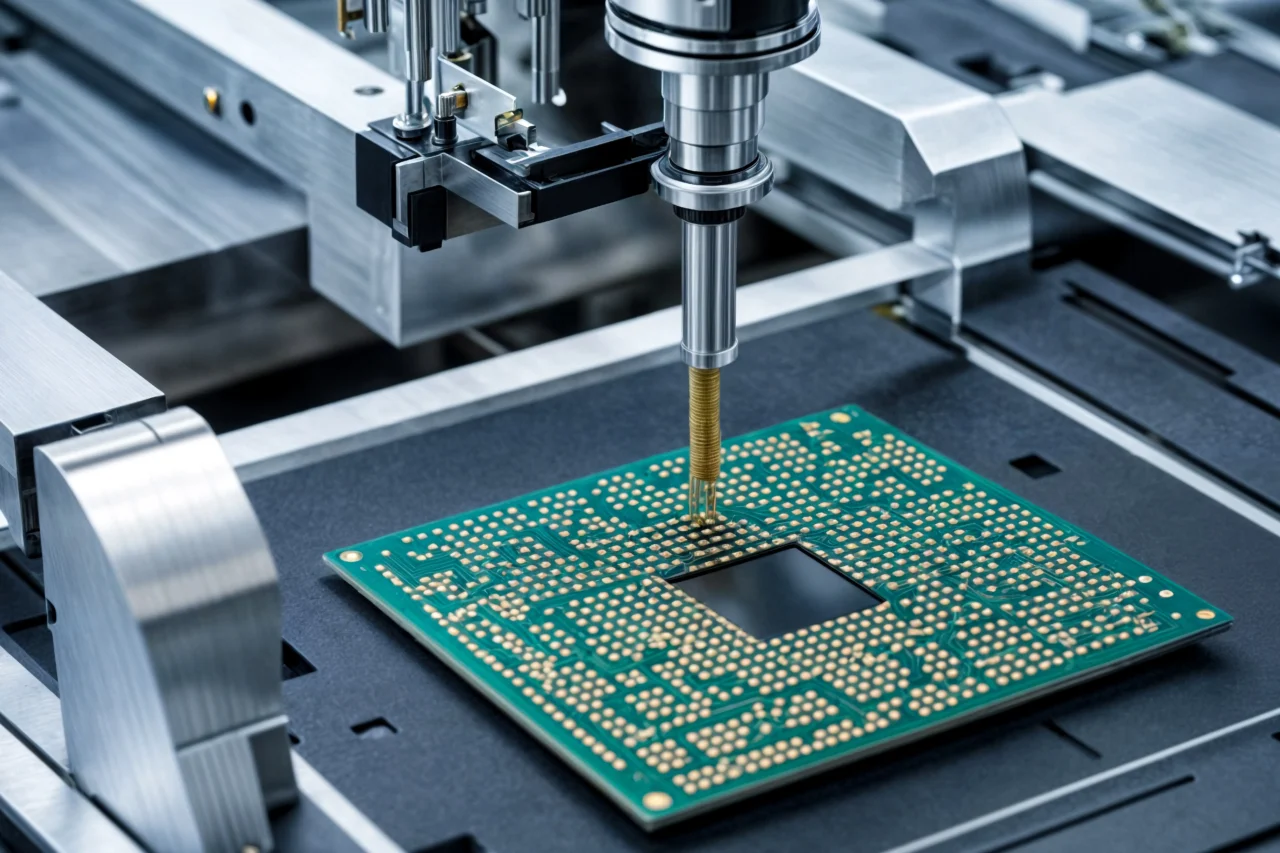

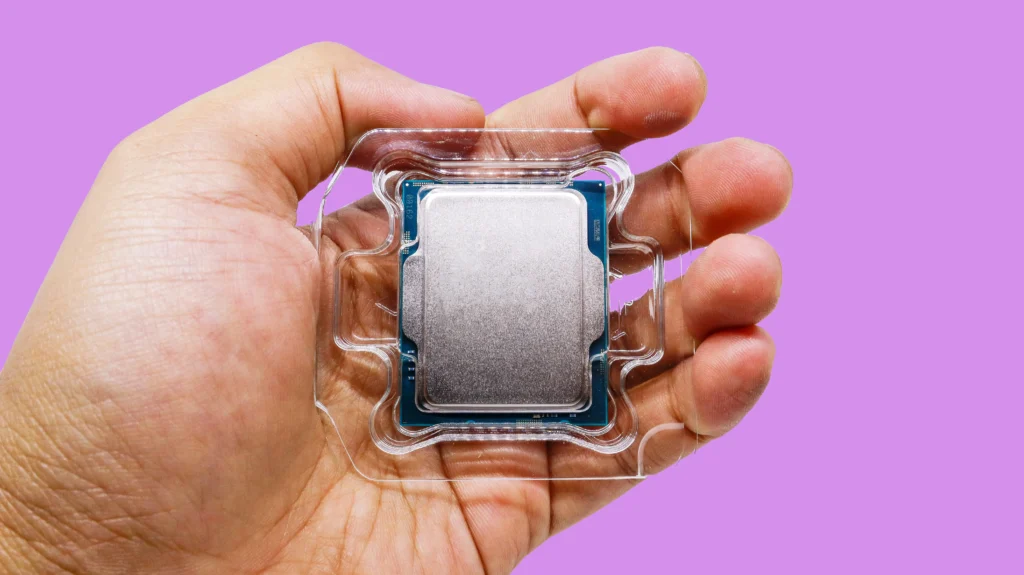

Electronics packaging has very specific requirements. Electronic components can be very delicate and any small scratch or minor damage can render them unusable. This leads to waste, delays, and increased production costs. As a result, packaging that provides a high degree of protection is mandatory.

In addition to physical protection, electronics packaging must also consider how much electric charge can accumulate on the packaging material since electronic components exposed to static can fail. This, once again, creates waste and costly delays.

Protecting Electronics from ESD Damage

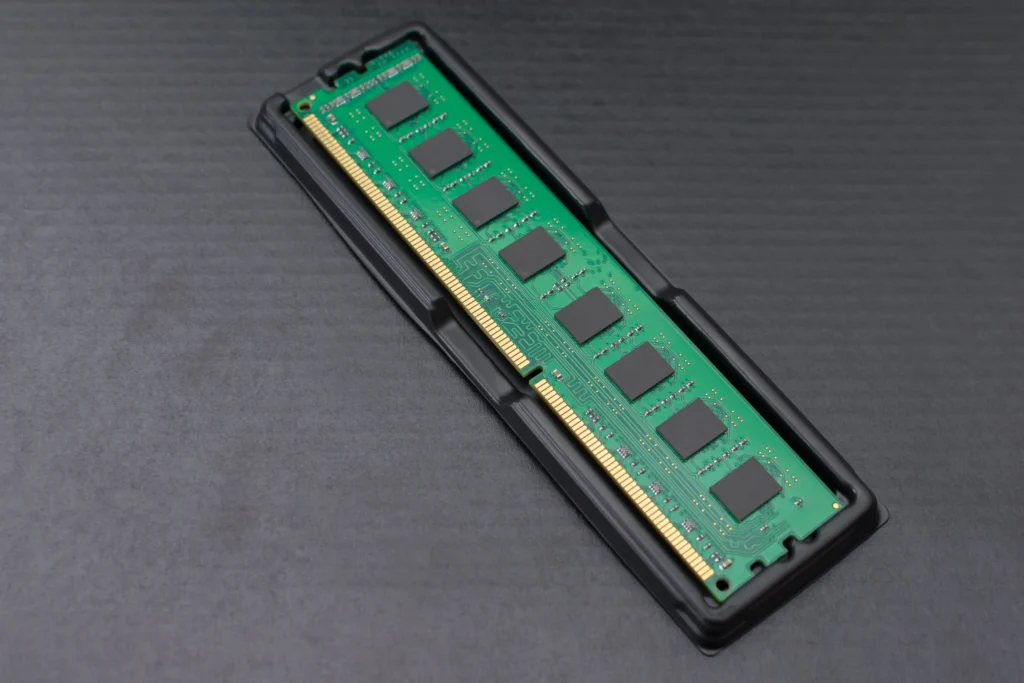

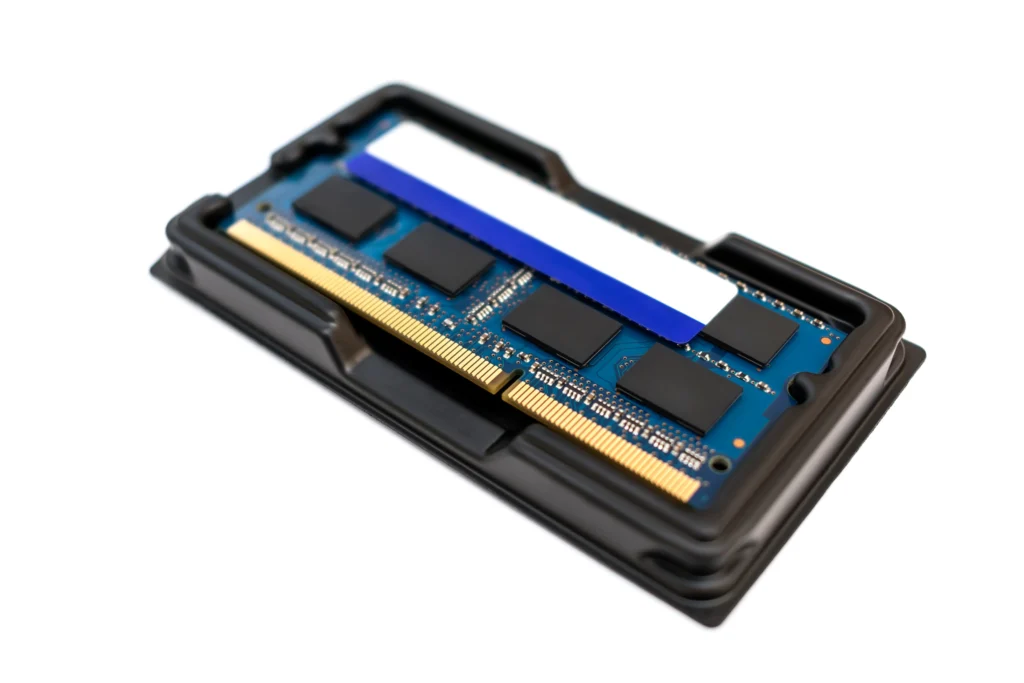

At Elmes Packaging, we utilize plastics with an electrostatic dissipative (ESD) or anti-static material. As a result, our packaging protects electronics from static damage. We have extensive experience designing effective packaging solutions where static is a concern. The use of our techniques can minimize costs for lost products, while reducing the need for additional packaging materials such as specialized sleeves and wrappings.

Maximizing Safety for Your Electronics During Transit

In addition to static safeguarding, we ensure your electronics are properly protected and free from impact and vibration during shipping or internal transportation. Our thermoformed packaging is custom-designed for your products, keeping them secure while allowing for easy removal through automated or manual processes.

Safety, compliance, and the protection of your electronics are critical. We adhere to all industry best practices and are ISO 9001:2015 and FSSC 22000 certified. We will continue to lead and evolve with the industry, keeping quality and safety as our top priorities.

Quick Turnarounds for Custom Electronics Protection

Whether you’re looking for a standard or custom design, we’re your partner. We understand there is no universal solution for electronics packaging, so we develop products to meet your exact specifications. If you require electronics packaging but aren’t sure what’s needed, our team will work with you from consultation to implementation to create the right thermoformed product.

Given the importance of meeting deadlines, we aim to keep lead times as short as possible and provide prompt design and delivery of your packaging requirements.