How to Choose the Right Thermoforming Company for Consumer Product Packaging

Your team has spent months perfecting a new consumer product, but when it comes time for packaging, the cracks—literally and figuratively—start to show. Trays don’t fit properly, materials fail under pressure, and lead times stretch beyond what your supply chain can handle. Suddenly, packaging becomes a bottleneck that threatens your entire launch.

A true thermoforming partner does more than supply packaging—they defend your product’s integrity, elevate its presence, and ensure it’s ready to perform at scale. The wrong choice? It could mean missed deadlines, rising costs, and a damaged brand reputation.

With so many options available, how do you separate a dependable manufacturing partner from a simple vendor? It comes down to a mix of precision, innovation, and long-term reliability. Whether you’re designing a new product or scaling production, this post will guide you through the key factors you should consider when choosing a thermoforming partner for consumer product packaging.

What Makes a Thermoforming Company Right for Consumer Products?

The best manufacturers align with your product’s unique needs, ensuring durability, cost-effectiveness, and visual appeal. They bring expertise in material selection, advanced forming techniques, and a streamlined process that supports everything from small-batch prototypes to high-volume production.

Not all thermoforming companies are equipped to handle the specific requirements of consumer product packaging. Some focus exclusively on medical trays or industrial components, while others specialize in food-safe solutions. Before shortlisting manufacturers, confirm that their capabilities align with your product’s needs.

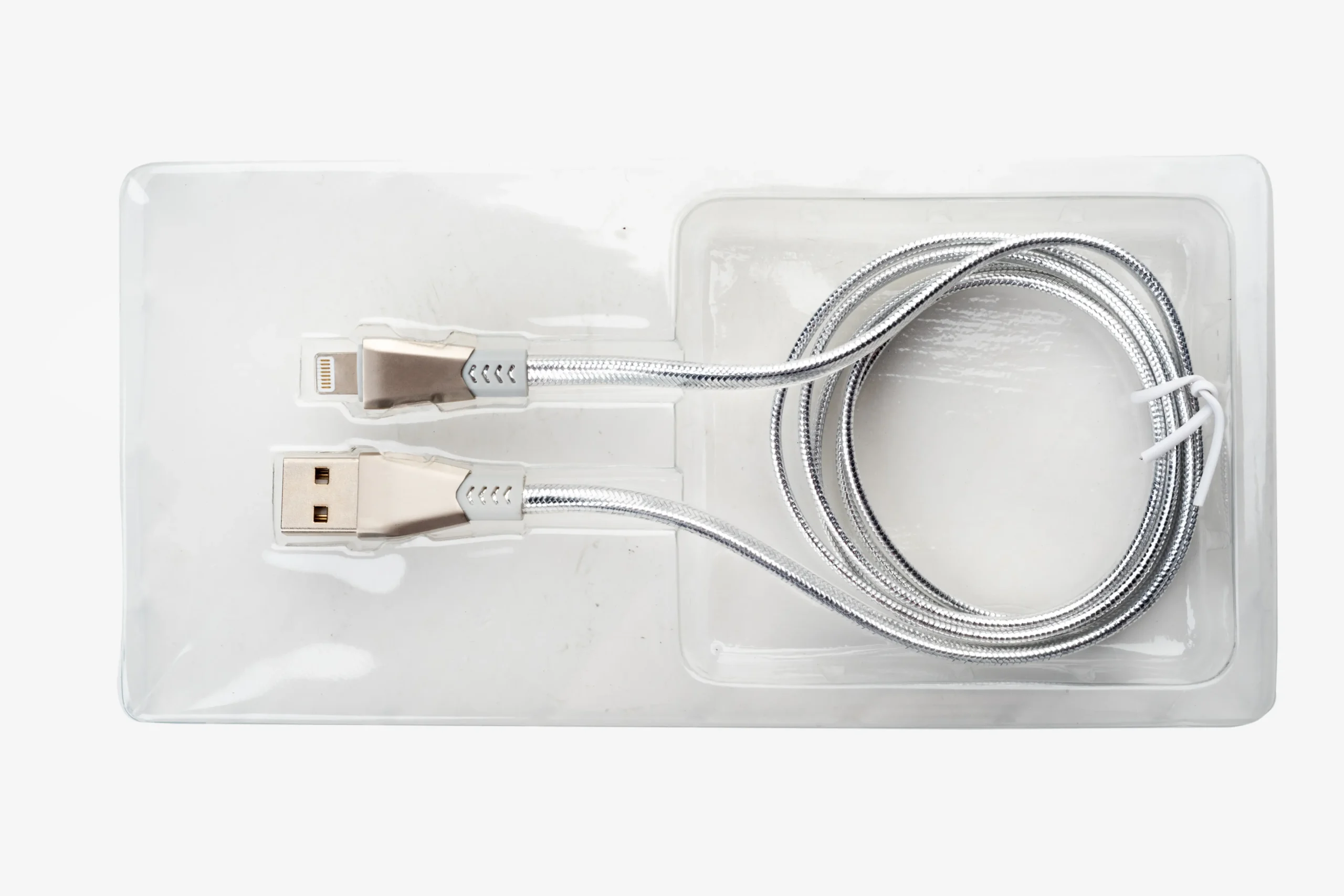

From consumer electronics to personal care products, packaging must do more than contain—it must protect, showcase, and enhance. The right thermoforming partner knows how to strike the perfect balance between strength and style—making sure your product stands out and stays protected, from production to the customer’s hands.

Balancing Cost Efficiency with High-Quality Standards

It’s tempting to compare thermoforming companies based solely on cost per unit, but a lower upfront price doesn’t always mean a better deal. Hidden costs—such as inefficient material usage, production delays, or high defect rates—can drive up expenses in the long run.

A cost-effective thermoforming company optimizes production for material efficiency and waste reduction. Confident packaging partners leverage lean manufacturing practices such as strategic prototype/production tooling, and supply chain agility to lower costs without sacrificing quality.

Scalability is also key—if a company struggles to accommodate fluctuating demand, unexpected costs from rushed production or secondary sourcing can pile up. Proactive partners with flexible capacity and forward-thinking logistics ensure cost efficiency without compromising quality.

Lead Times and Supply Chain Reliability: Avoiding Costly Delays

A well-designed package is useless if it doesn’t arrive when you need it. Lead times can make or break a product launch, and supply chain disruptions can create cascading delays across your entire operation.

The best thermoforming companies anticipate challenges. They have contingency plans—diversified material sourcing, redundant production facilities, and streamlined logistics partnerships—that minimize risks. Before committing, ask about turnaround times and how they handle potential delays.

Does their location impact shipping times? Do they maintain raw material stock to prevent shortages? A reliable partner will be transparent about these factors and have strategies in place to keep your production on track.

Collaboration and Communication: The Difference Between a Vendor and a Partner

A true thermoforming partner does more than fulfill orders—they actively contribute to your packaging strategy. Strong communication ensures that potential issues are identified early, whether it’s optimizing material choices, refining design specs, or navigating regulatory changes.

Pay attention to how a company engages during the initial consultation. Do they ask insightful questions about your product’s lifecycle, distribution channels, and sustainability goals? Do they offer proactive solutions, or simply provide a price quote and move on?

The right partner feels like an extension of your team, offering ongoing engineering support, material insights, and continuous process improvements to help your packaging evolve alongside your product.

Quality Assurance: Certifications and Compliance You Can’t Overlook

In consumer product packaging, even minor defects can lead to costly recalls or damage to your brand’s reputation. That’s why a thermoforming company’s commitment to quality control should be non-negotiable.

Certifications such as ISO 9001:2015 signal that a manufacturer follows rigorous quality management standards. These frameworks ensure that every production run meets strict consistency, safety, and performance criteria.

Ask potential partners about their inspection protocols. Do they conduct in-line quality checks? How do they handle deviations in material thickness or forming precision? A manufacturer with robust quality control prevents issues before they reach your supply chain.

Customization vs. Standard Solutions: Finding the Right Balance

Not every project requires custom packaging, but relying solely on off-the-shelf solutions can limit product performance and brand impact. The key is finding a thermoforming company that offers both flexibility and strategic guidance.

If your product has unique dimensions, requires enhanced security, or needs a premium unboxing experience, customization is essential. A manufacturer with in-house tooling capabilities can create molds tailored to your exact specifications, ensuring a perfect fit while maintaining production efficiency.

However, custom tooling can drive up costs and lead times. A knowledgeable thermoforming partner will help you assess whether modifications to existing designs can achieve the same result at a fraction of the cost. The ability to strike this balance—offering tailored solutions without unnecessary complexity—sets resilient manufacturers apart from generic suppliers.

Choosing a Thermoforming Company That Can Scale with Your Business

A great thermoforming company grows with you. Whether launching a new product or ramping up production for a growing market, manufacturers must offer the flexibility to handle low-volume custom orders and high-volume mass production without compromising quality.

Scalability also extends to supply chain management. A partner with strong supplier relationships can secure high-quality materials at stable prices, reducing the risk of disruptions. Ensure your manufacturer has the capacity, agility, and expertise to support your growth at every stage.

The Role of Sustainability in Thermoforming Packaging

Consumers are more environmentally conscious than ever, and sustainability in packaging is no longer optional. Choosing a thermoforming company that prioritizes eco-friendly materials and energy-efficient processes ensures that your packaging aligns with evolving industry expectations.

Post-consumer recycled (PCR) plastics, biodegradable alternatives, and closed-loop recycling programs all contribute to reducing packaging waste. Manufacturers like Elmes lead the way in sustainability by achieving zero-waste manufacturing, repurposing production off-cuts, and maximizing material efficiency.

Sustainability also extends to logistics—lightweight packaging and proper denesting reduce shipping emissions, and stackable designs improve freight efficiency. A forward-thinking thermoforming partner helps brands meet sustainability goals without sacrificing performance.

Finding a Thermoforming Partner That Fits Your Business

The right thermoforming company provides more than packaging—they become a strategic partner, integral to your operations. From material selection and precision forming to sustainability and scalability, every decision impacts your product’s success.

By partnering with an experienced thermoforming manufacturer that prioritizes innovation, cost efficiency, and reliability, engineers can make informed decisions that support their product’s success in a competitive market.

Choosing the right thermoforming company today ensures smoother production, lower costs, and a stronger brand presence tomorrow. So, take the time to select a partner who can meet your current needs and grow with you as your business evolves.

Looking for a thermoforming company that delivers high-quality, cost-effective, and sustainable packaging? Get a quote today and let’s create packaging that sets your product apart.